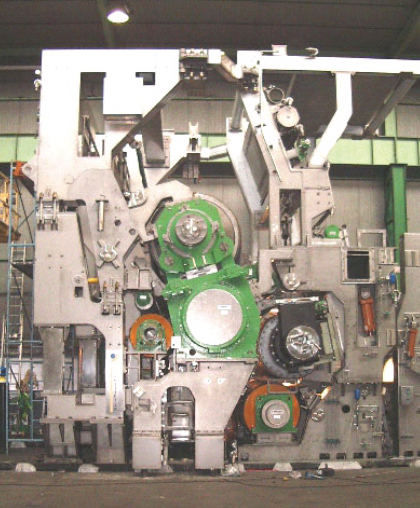

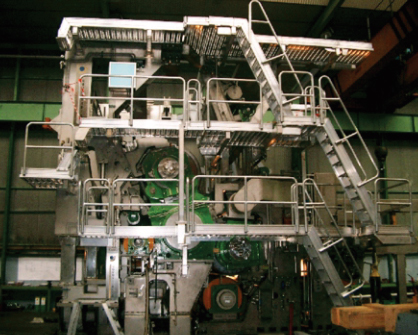

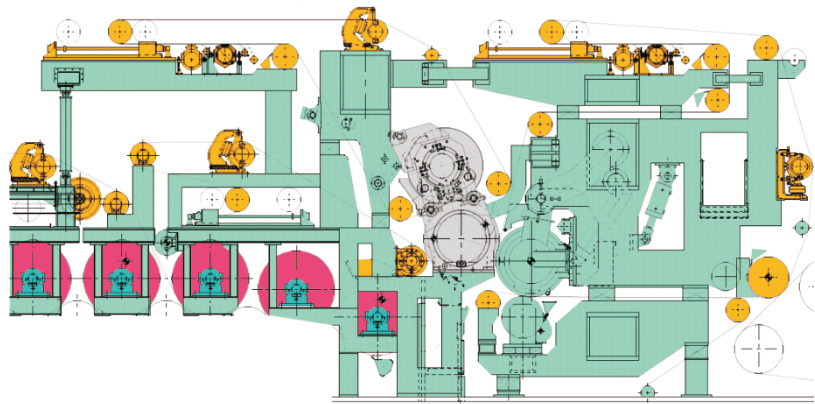

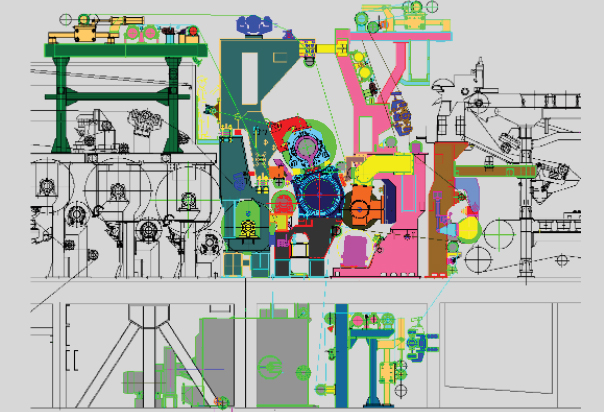

The multi-nip press part – TRI-NIP is one of the possible configurations of press rolls in the press part. The TRI-NIP is a compact set of four press rolls forming three nips. It is used particularly for the conception of the press part with a shoe-press module in the position of the third nip. As a central roll of the 1st and the 2nd nips, a three-chamber suction roll is used, containing two chambers with a high-vacuum, ensuring the suction of water out of the felt in the point of the nip, and one chamber with a low-vacuum, ensuring the transfer of the paper from the 1st nip to the 2nd nip. A smooth press roll without a felt is placed in the position of the central press roll of the 2nd nip and the 3rd nip. The roll is dimensioned for two nips with a linear load up to 1200 kN/m. The smooth roll surface ensures the transfer of the paper from the 2nd nip to the 3rd nip.

A combination of a shoe-press module and a stationary press roll is used in the position of the 3rd nip, permitting to press with a higher linear load in the wider nip and to achieve a better dewatering of the paper.

The main advantage of the multi-nip press part TRI-NIP is the shortening of the paper track in the press part and the elimination of free draw forces. During its passage through the press, the paper remains in a permanent contact with one of the rolls and it is not necessary to equip the press part with additional guide rolls.

The compact configuration of press rolls considerably shortens the press part. The use of the shoe-press module in the position of the 3rd nip permits to reach the dryness volume after the press higher than 50 %.

The multi-nip press part TRI/NIP with the shoe-press module is useful particularly in high-speed machines, enabling to reach compact dimensions of the press part, a high volume of dryness after the press and the stability of the paper during its passage through the press part.

Main parts

- Pick-up – one-chamber or two-chamber suction roll for the transfer of the paper from the wire part into the press part

- Bottom press roll with felt (Ø 980 mm with coating)

- Three-chamber suction press roll with felt (Ø 1.120 mm with coating)

- Central press roll (Ø 1.250 mm with coating)

- Bearing structure

- Shoe-press module

- Nosná konstrukce

- Equipment for the felt guiding, cleaning and dewatering.

Material

- The bearing structure and guide rolls are made of common steel

- the press rolls embedding is made of cast iron

Accessories

- Roll removal equipment

- “Jumbo” press drive (mechanical and § electric part, control included)

Scope of delivery

- Complete machine in accordance with the main parts description

- Accessories optionally